Museum of the Future

Project description

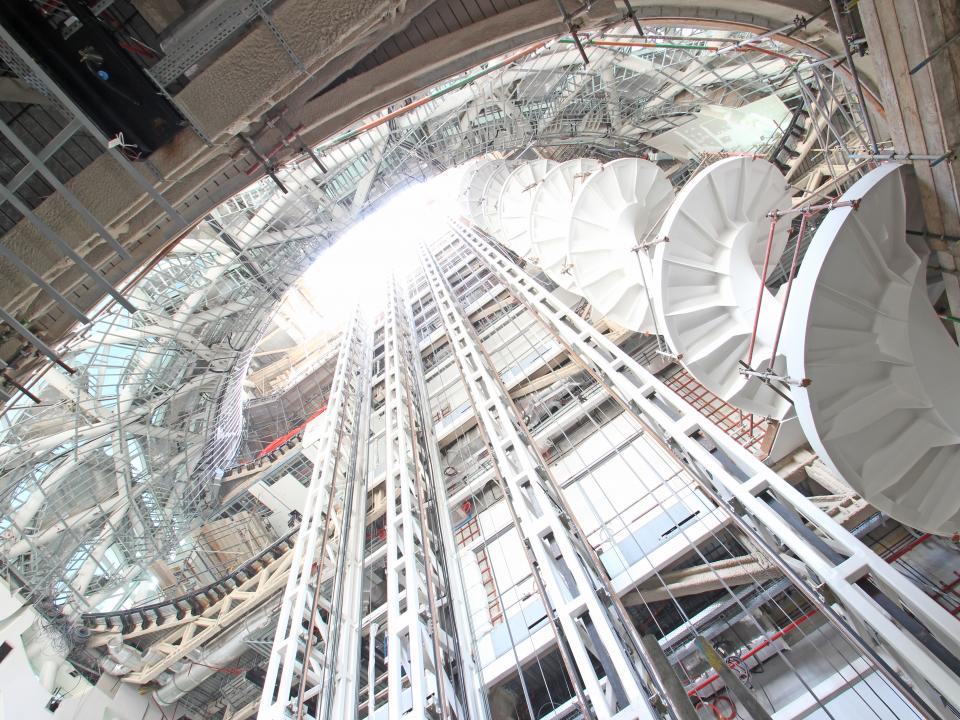

Museum of the Future is one of the most innovative buildings in the world in terms of design, engineering, and construction. It consists of an 11-storey torus-shaped building located in Dubai. Inspired from feng shui, its form represents the earth and the limitless imagination of the sky with a void in the middle symbolizing the unknown. The museum aims to become an incubator for innovation and invention instead of a repository of artifacts. Its facade will also combine engineering, art, and poetry as it displays glass windows in the form of poems and quotes from H.H. Sheikh Mohammed Bin Rashid in a beautifully crafted Arabic calligraphy. Considered one of the most complex architectural projects in the world, the Museum of the Future is a symbol of architecture that pushes back the boundaries with more efficient materials. Also an example of sustainable building, it will have the LEED Platinum status which is the highest level of LEED certification.

Contractor

Plafond

Plafond is a leading Dubai based multi-disciplinary Fit Out, MEP and Facilities Management specialist that offers a comprehensive range of services tailored to meet the client’s needs. The specialist divisions of our business meet the needs of a wide range of industries, sectors and project complexities across the Middle East and GCC. Plafond is unique in the region, offering end to end solutions to all business sectors. This makes us the one stop solution for all building needs. We believe in providing our clients with a satisfactory and hassle-free experience during the project tenure. Our management team is trained for and practices, ‘Lean Six Sigma’ which contributes to the delivery of high quality projects, effectively and efficiently. Our success is driven by the strength of our people and our commitment to surpassing client’s expectations. Plafond strives to ensure each and every project is completed on time, within budget and to the highest standard. Sustainability and quality remain at the heart of everything we do. We embrace environmental principles and encourage our clients to do the same, as a result, our environmental initiatives have resulted in the company gaining ISO14001 accreditation. The company was also awarded ISO9001 accreditation in recognition of our commitment to customer service and quality in delivery and the BH OHSAS18001 accreditation in recognition of our occupational health and safety management systems.

- The architectural complexity of the Museum of the Future had pushed back our technical boundaries to invent a new proven solution of internal wall lining system that is dynamic to accommodate the multiple curves and shapes and therefore meet the building’s design requirements

- The great collaboration of Gyproc’s Technical development and Technical Academy working closely with the installer Plafond made it a success to design, BIM model and execute such artistic internal lining system within a challenging short time frame and budget

- More than 80 on-site visits were done from Gyproc Technical Academy team and Gyproc technical development team spent more than 200+ hours of design support to site.

Key Challenges

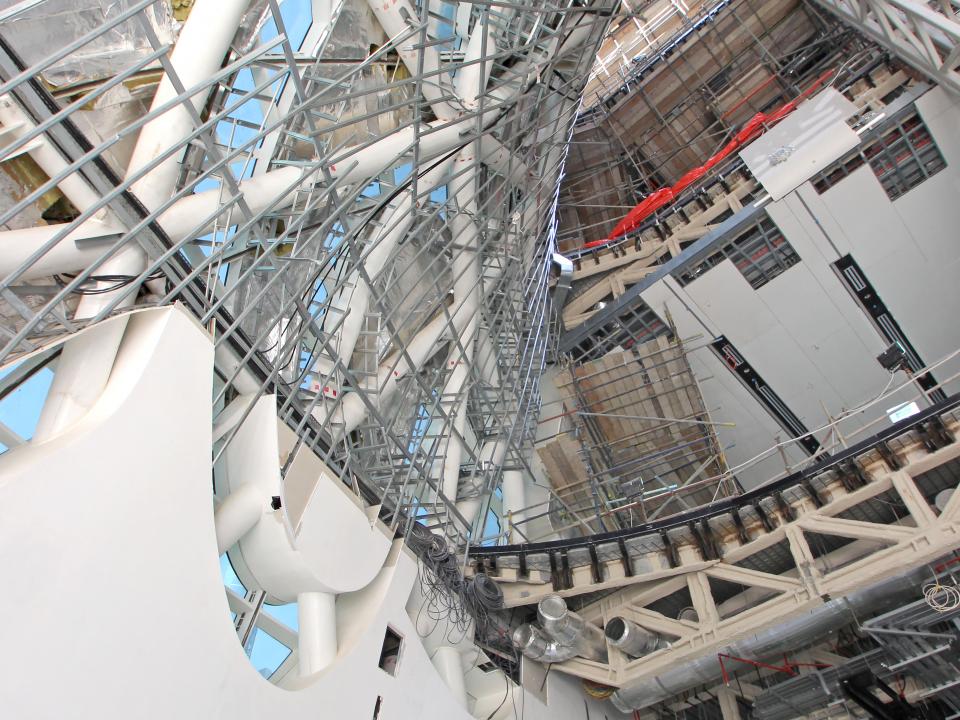

Technical challenges raised by the specific shape of the project, a tailor-made offer combining different ideas and components had to be developed stretching Gyproc technical team to new limits in offering bespoke design that had to be structurally validated.

Time constraint was a key challenge for Plafond & Gyproc team, as the design for internal wall cladding started as the actual project built up was happening on site.

Modeling it over the BIM and executing the job on site has been a magnificent challenge and coordination to Plafond & Gyproc teams, as tilting and pivoting the Gypframe® structures at various angle to reflect the three dimensional curved nature of the building internally and in the reveals.

Due to the unique curvature of the building, there has been many difficult to reach spaces to build the Gypframe® lining system.