Leeds University Technical College

Project description

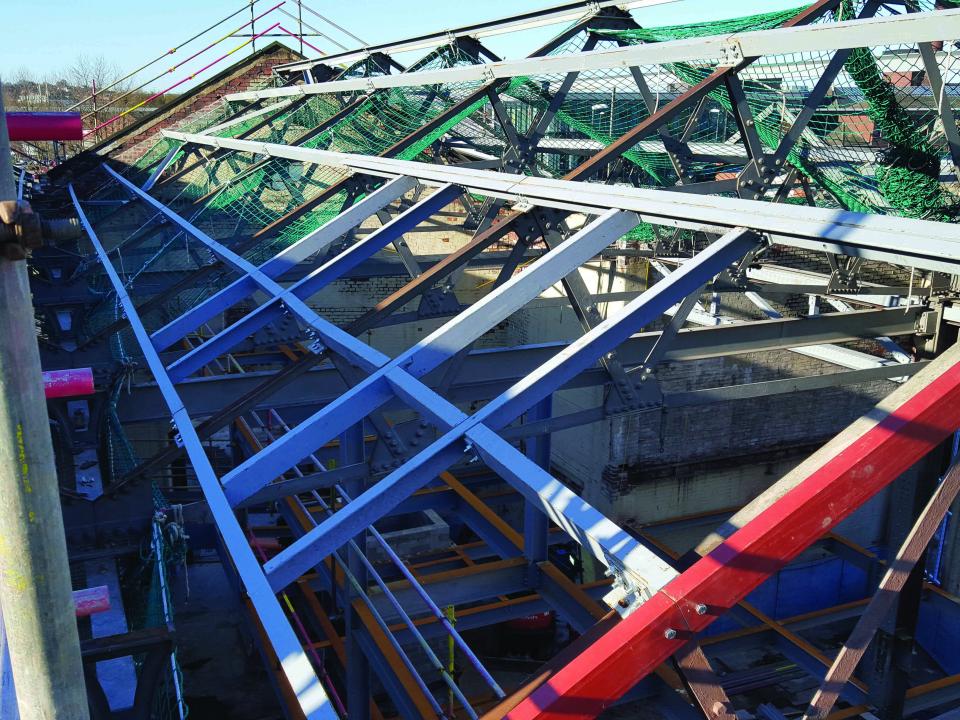

The sympathetic restoration of this Grade II Listed Victorian factory has breathed a new lease of life into an historic piece of Leeds’ vivid manufacturing history. Transforming the disused Braime metal pressing factory, Leeds UTC is a state-of-the-art specialist college for 14-18 year-old engineering students. The space for the college was created by sectioning off a corner of the original building, using an internal partition. Due to the listed nature of the building, the original brick facades and structural steelwork had to be retained, but essentially the college is a new building wrapped in the two historic external facades. Developing the site required great technical skill to deliver the high standards of lighting, acoustics and durability required by a modern education facility – while still paying homage to the building’s heritage.

Contractor

Sparta Systems Ltd

A young and dynamic company, Sparta Systems boasts a wealth of varied experience gained over the course of a decade. Members of the Sparta Systems team have played key roles in the delivery of sub-contract packages on numerous projects including: hospitals, schools, MOD buildings, student accommodation, health centres and apartments.

Key Achievements

- Excellent partnership working between the architect, contractors and British Gypsum to rationalise specifications and overcome technical challenges.

- High levels of technical skill from the installation team have delivered an impressive finish throughout the project, with no 12-month defects reported.

- Project complete on time and to an extremely short schedule, with the partitioning and drylining work taking just 20 weeks.

- End result is a landmark building that sets a new standard in technology education.

Key Challenges

Updating a Victorian building to deliver modern performance standards, while also protecting its unique heritage.

Overcoming access difficulties in the roof area, without damaging the existing steel structures.

Delivering an excellent standard of finish across the project, including areas with extremely high walls and complex architectural details.

Working to a very tight schedule to deliver the completed college in time for the new academic year.