Technodrome Room

Project description

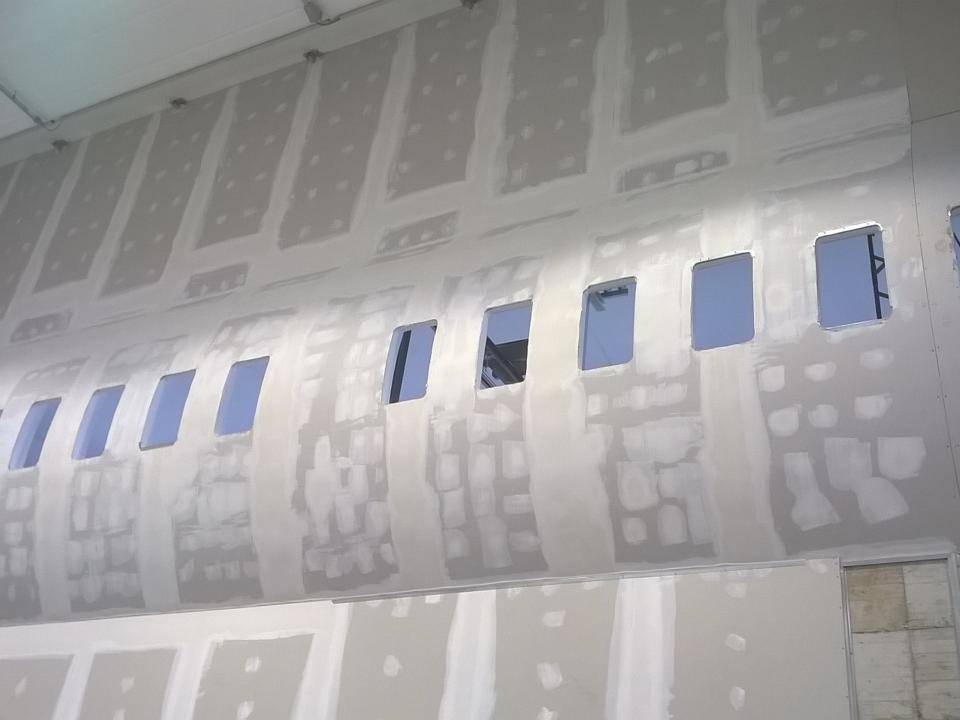

Since 1980 Jobs has been producing high-performance machining in the Aerospace/Aeronautics, Car Industry, General Engineering and Energy fields. Hence the idea of creating a suggestive multi-functional room called “Technodrome”, designed in the shape of a fuselage inside a new production plant of about 3,000 square meters. A sort of “airplane inside the factory” that expresses what the company is able to do and that has been designed to host conferences and meetings on the topics of innovation in aerospace and automation. The main characteristic of the project is the curvilinear shape of the meeting room, so to give the idea of being in an airplane. To complete the project, the most performing Saint-Gobain Gyproc solutions have been used: Gyproc® Flex 6 for walls and Gyptone® Big Curve Activ’Air® slabs for ceilings. This solution is able to ensure the maximum technical performances and high flexibility of application even in the presence of volumes and curved shapes.

Contractor

Isolservice Fidenza s.r.l.

Isolservice Fidenza s.r.l. was founded in 2003 and specialized in the field of fire protection, plasterboard applications such as walls and ceilings, technical and raised floors and paintings. The company boasts a wide technical specialization in the field of interior finishings, entrusting its work to expert workers and external teams offering high professional performances.

Key Achievements

- Collaboration with a historic customer with whom we carry out many technical projects, and where attention to details is extremely important

- Both architects and contractors were so precise to recreate the environment that staying in the room evokes the feeling of being in a plane, with the same shapes and lighting

Key Challenges

The request was unusual, so the competency and the ability of the applicator was the fundamental key element for the work to be done in the correct way, achieving both aesthetics and performance.